文章內容

Types and Materials of Packaging

❒ Interior and exterior of IC package

The Integrated Circuit (IC) will generate a lot of heat during operation, especially IC with more complicated structure or smaller processing line width, such as CPU or DSP. Usually the higher the integration level means the higher dense level of CMOS, so the generated heat will be more and then the IC will need the material with better heat dissipation performance for packaging.

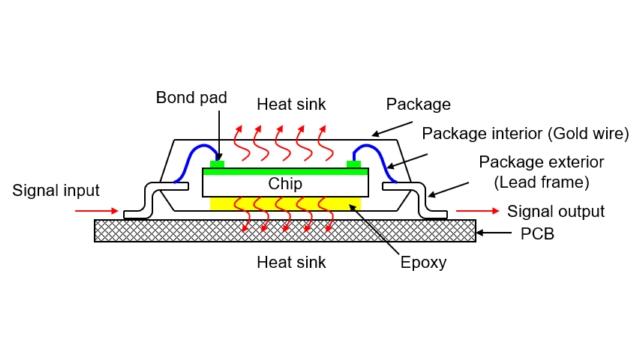

In Fig. 1, the IC package may be divided as “interior” and “exterior.” To understand IC package, we will not be confused by dividing as interior and exterior.

➤ Package interior: Referring to the connection method between bond pad on the chip and the lead frame (or lead carrier) inside the package which usually cannot be seen from the appearance

➤ Package exterior: Referring to the connection method between the lead frame (or lead carrier) and the Printed Circuit Board (PCB) outside the package which would be the outlook of IC.

Figure 1: Interior and exterior of IC package.

❒ IC packaging material

The IC package can protect the chip and isolate from moisture and dust. The lead frame after packaging may be welded on a PCB, as shown in Fig. 1. The material used for packaging case should consider the cost and heat dissipation performance. The Integrated Circuit (IC) will generate a lot of heat during operation, especially IC with more complicated structure or smaller processing line width, such as CPU or DSP. Usually the higher the integration level means the higher dense level of CMOS, so the generated heat will be more and then the IC will need the material with better heat dissipation performance for packaging. The ordinary materials for packaging case may have the following three types:

➤ Plastic package: The heat dissipation of plastic package is the worst. This is the reason why the pot handles are usually made of plastic. However, the production of plastic package is the easiest and the cost is the lowest, so the plastic package is normally applied for IC with simple structure and having less CMOS in the chip.

➤ Ceramic package: The heat dissipation of ceramic package is better. This is the reason why a ceramic cup may be heated immediately once pouring hot water into the cup. Obviously, the heat conductivity of ceramic is very good. However, the processing of ceramic package requires sintering, so the process is more difficult and the cost is higher. The ceramic package is normally applied for IC having more CMOS in the chip, such as CPU, Northbridge chip, etc.

➤ Metal package: Among the materials, metal has the best heat dissipation performance. Unfortunately, metal will conduct electricity, so it cannot be directly used as packaging case, otherwise the metal case will cause the short-circuit effect of lead frame. Smart scientists had thought of first using ceramic or plastic package and then replacing the ceramic or plastic above the packaging case with metal case. Therefore, the ceramic or plastic below will not cause the short-circuit effect of lead frame and meanwhile the upper metal may rapidly dissipate the heat. It is called “metal package.” The metal package has the best heat dissipation performance, but the processing is more difficult and the cost is higher, so the metal package is normally applied for IC having more CMOS in the chip. Currently, many CPUs and Northbridge chip in a chipset all utilize the metal package.

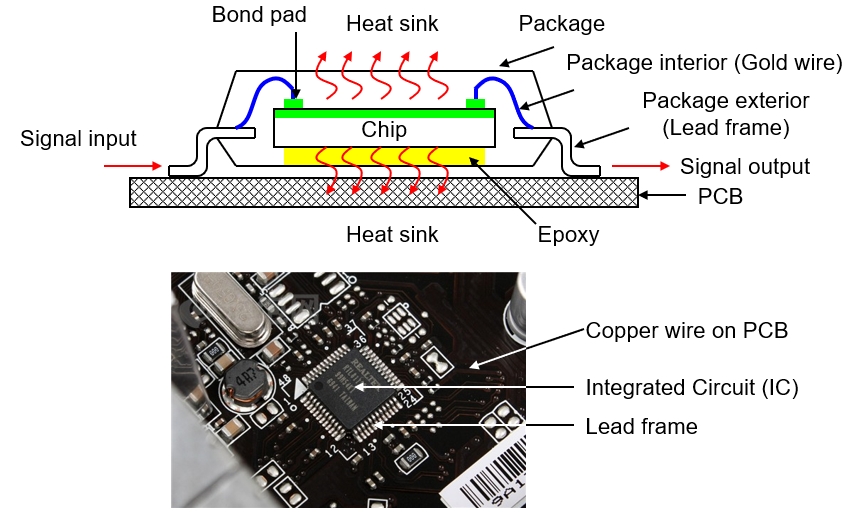

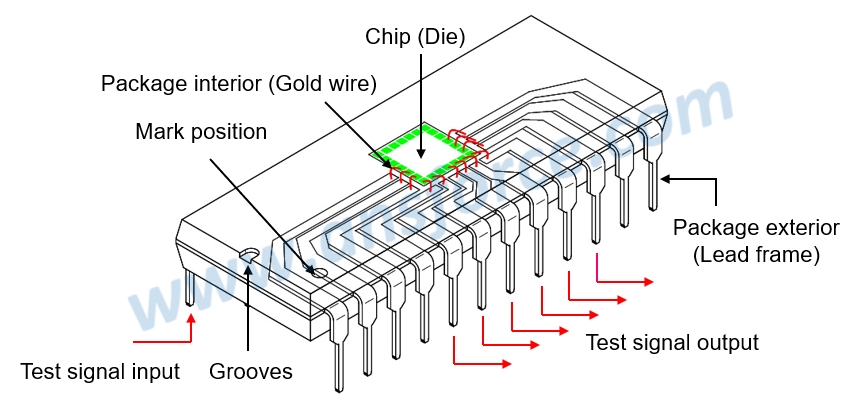

❒ Lead frame

The structure of lead frame is shown in Fig. 2. One end of the gold wires is aggregated and connected onto the bond pad around the chip, and the other end is spread to connect onto the Printed Circuit Board (PCB). Remember that IC must be connected onto the PCB to operate with other ICs. The lead frame has multiple metal pins for spreading out the aggregated electric signals. Because the bond pad is made around the chip and the chip is very small and the bond pad too (about 10μm) but the circuits on PCB are usually thicker (about 100μm), the lead frame must be used to spread out the aggregated electric signals. The disadvantage of using lead frame is that only the wire bonding may be applied, so the lead frame can only be applied for ICs with less metal pins.

Figure 2: Structure of lead frame.

❒ Laminate substrate

There are many types of laminate substrate, usually used as “flip-chip substrate.” The structure is shown in Fig. 3(a). Laminate substrate is mainly used by flip-chip package and has exactly the same function as lead frame, i.e. spreading out aggregated electric signals with different structures. The lead frame is to directly fold the metal pins as centipede feet; and, the laminate substrate buries the metal circuits in a very small plastic plate with a process similar to making PCB. In fact, these metal circuits also have their one end aggregated and the other ends spread out, as shown in Fig. 3(b).

.jpg)

Figure 3: Structure of laminate substrate.

【Remark】The aforementioned contents have been appropriately simplified to be suitable for reading by the public, which might be slightly differentiated from the current industry situation. If you are the expert in this field and would like to give your opinions, please contact the writer. If you have any industrial and technical issues, please join the community for further discussion.